From software simulation to the finished LED!

Our aim at Chips 4 Light is to offer our customers individual ideas and solutions before the first prototype is physically on the table. With our expertise and the necessary hard- and software equipment, we can do just that, customized LED and prototype production.

After specifying the requirements for the LED, the circuit board design will be realized with SolidWorks PCB which includes schematic, individual footprint, layout design. A special feature here is that the designed circuit board can be directly integrated into SolidWorks.

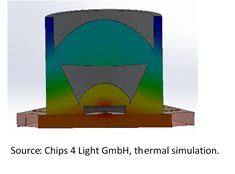

With the Flow Simulation (add-in software for SolidWorks) we can simulate the heat distribution of the component. The LED chip is defined as a heat source. Then it becomes visible how much heat is transferred from the source to the other components in the design (other LED chips, resistors, circuit board, etc.). This simulation helps to select appropriate materials for the whole LED design. Additionally, hotspots / bottlenecks can be localized and the structure can be optimized. Everything is still a simulation on the PC.

With the Flow Simulation (add-in software for SolidWorks) we can simulate the heat distribution of the component. The LED chip is defined as a heat source. Then it becomes visible how much heat is transferred from the source to the other components in the design (other LED chips, resistors, circuit board, etc.). This simulation helps to select appropriate materials for the whole LED design. Additionally, hotspots / bottlenecks can be localized and the structure can be optimized. Everything is still a simulation on the PC.

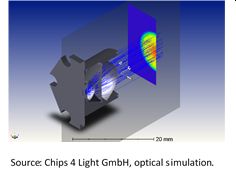

In addition to the thermal conductivity, the beam characteristics of the light source (e.g. an LED chip, laser diode ...) are shown via Zemax OpticStudio. A diversity of lens types such as spherical lenses, aspherical lenses, TIR lenses, Fresnel lenses, CPC, mirrors… can be simulated in their beam shaping. Parameters for beam shaping are, for example, the optical elements, all materials, the wavelength and the size of the light source.

In addition to the thermal conductivity, the beam characteristics of the light source (e.g. an LED chip, laser diode ...) are shown via Zemax OpticStudio. A diversity of lens types such as spherical lenses, aspherical lenses, TIR lenses, Fresnel lenses, CPC, mirrors… can be simulated in their beam shaping. Parameters for beam shaping are, for example, the optical elements, all materials, the wavelength and the size of the light source.

Our team of experts considers all parameters for the development of an LED. The integrated software packages allow an efficient prototype simulation. What is the benefit for our customers? A fast, cost efficient and optimized use of resources. Ask us for more details. info@chips4light.com